Maintenance Tips to Extend the Life of Machinery and Equipment

While routine maintenance of production equipment may not sound like the simplest part of running a business, keeping the core part of your manufacturing business in great condition often makes the difference between meeting and missing the delivery dates. On top of that, regular maintenance might identify potential safety problems long before they occur, as well as keep the product quality in line. You can even save money, as these actions prolong equipment life and optimize the machine performance. Let’s look at some of the universal maintenance tips.

1. Schedule maintenance based on usage

Although some equipment service manuals prompt the operator to perform certain maintenance tasks on a time-based level, waiting for these might interfere with the production. On the other hand, if these tasks are scheduled in advance according to machine usage, they are less likely to be forgotten or overlooked in favour of meeting a production deadline. For example, if you use a machine eight hours a day, a maintenance schedule of once in every six months sounds reasonable. However, if you’re squeezing the machine into three-shift operation, you might have to schedule the maintenance once every three months.

2. Invest in operator training

Since many types of large machinery have more than one operator, it’s important that one of the ongoing inspections include supervising the correct usage of the equipment. Large machines should always be inspected on purchase, and by that time, operator training should be completed. However, the training needs to go on, as employees come and go and skills become rusty, which leads to potential breakdowns. If needed, operator manuals should be rewritten in simpler language, with short manuals printed and given to each operator separately. If you’re running a paperless environment, operators should be provided with the latest version of each manual.

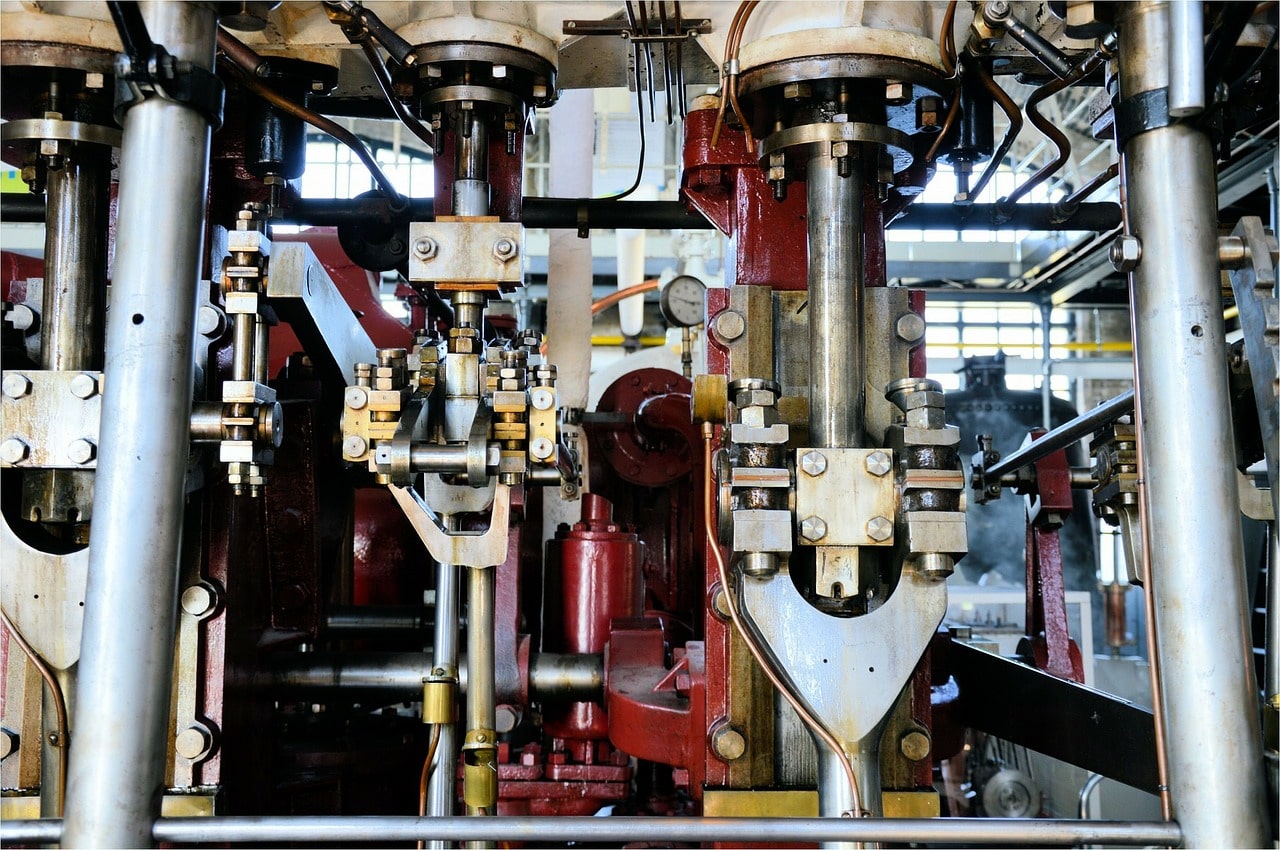

3. Inspect for signs of wear

Even if your equipment is used responsibly and properly, working conditions that include vibrations, shock, friction, and high temperatures may contribute to wear and breakdown of individual parts. Gears and belts that are misaligned might cause unnecessary vibrations, while shock results from either accidents or poor operator technique. When combined with poor lubrication, work parts may cause friction with results in higher operating temperatures, that accelerate further wear of machinery. Any wear and tear that is discovered by an inspection should be addressed promptly by a repair or replacement of the affected part.

4. Adjust maintenance depending on the environment

Besides reading the manual and training the operators, another question that needs addressing is the workplace environment. A desert with dust and sand in the air is nothing like a heated factory hall. There is also a question of environmental hazards of malfunctioning equipment. One of the examples is the oil and gas industry, where maintenance instructions are rarely separated from workers’ safety and environmental regulations. Oil and gas operations are not only characterized by large size and heavy use of work equipment, but also high price and repair costs. This is why it’s important to use only quality oilfield equipment and go with trusted vendors who are committed to following with the full range of services, as well.

5. Hold employees accountable

When you’ve identified the preventive maintenance tasks for every piece of equipment, you need to assign follow-through actions to a maintenance coordinator, machine operator, or dedicated maintenance personnel. These employees should be held accountable for the maintenance operations, by signing off maintenance schedules, either on a sheet attached to each machine, through asset management software, or through weekly and monthly cards submitted to supervisors. Whichever method you agree upon, make sure the maintenance schedule you’ve set is followed consistently.

6. The role of management

Failing to schedule preventive maintenance, extending maintenance cycles in favour of meeting the production needs, and instructing employees to keep maintenance costs down not only sends a wrong message, but ultimately costs an organization more in machine downtime and repair costs. If production needs continue to be favoured to scheduled maintenance tasks, the only solution is to have the equipment maintained during off hours. On the other hand, when discussing budget needs, the management needs to realize that failing to perform preventive maintenance often results in much higher expenses, especially if a machine breaks down in the peak of a busy production cycle.

Following these six maintenance tips doesn’t only extend the useful life of your equipment, but also provides a greater value to your organization if you’re ready to distribute and share this maintenance know-how across all your systems.

About the author: Mike Johnston is a business and lifestyle blogger from Sydney. He is a regular writer at Smooth Decorator and contributor on several financial, real estate and environmental blogs. Mike’s goal is to create and share meaningful content that helps and inspires people.